Calvin Glover, Meter Field Tech III, starts an electric meter.

With the start of spring, we’re bringing new life to our “Spotlight On” series, now offering a behind-the-scenes look at how each GUC department enhances the quality of life for our community. This month, we’re kicking it off with the Electric Department’s Meter Section.

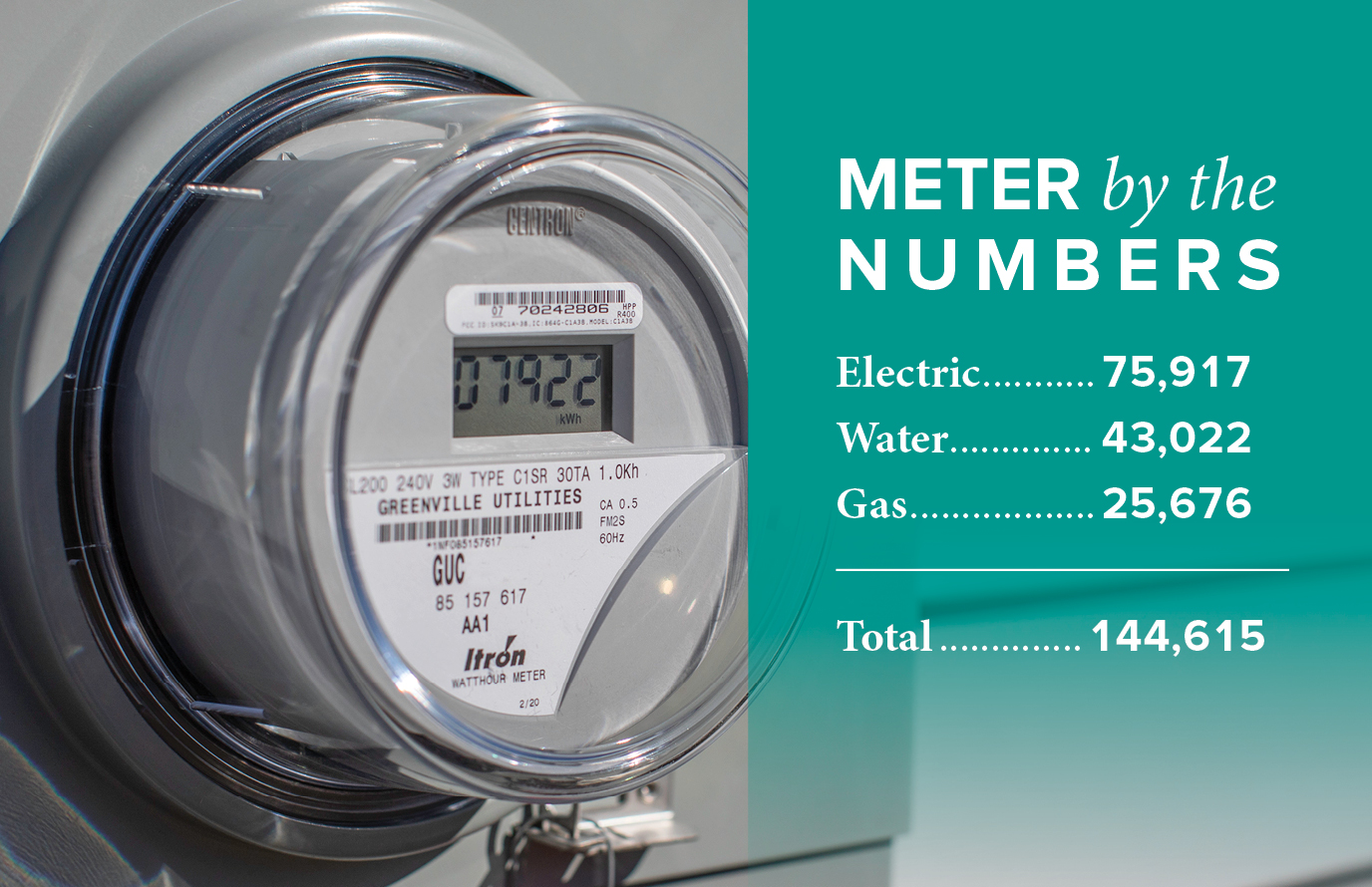

For Greenville Utilities Commission, everything begins and ends with meters. From a new meter service coming online to transferring or cutting off, the Meter Section is the heartbeat of GUC, and as more meters go in service, the stronger that heartbeat becomes.

The Beginning . . .

Elliot Jones, Meter Technician I, drives slowly through a subdivision off Frog Level Road, as the mobile collection system rhythmically beeps with each meter read, mimicking a heart monitor.

On this day, Elliot must stop to check the water meters that were not automatically read by the software. When a meter doesn’t read, he gets out of the truck and finds the meter by pushing inches of mud and grass away from the lid before lifting it. He pulls out the encoder receiver transmitter (ERT) that is submerged under four inches of water, and the icon on his iPad clicks from yellow to green, indicating it was finally read.

“After it rains, the routes can take longer because these meter boxes usually have water in them,” Elliot said. “So, we have to pay attention and stop at each one that doesn’t pick up a read.”

As he drives through subdivisions, he periodically flips his beacon light on and sits for a minute, then the yellow indicator on his iPad turns green, the water meter reads, and he drives on.

With 241 total routes in the entire GUC system, some reading routes have around 7,000 meters. All reading sections are carefully considered and outlined by Meter Supervisor (Reading) Jamie Braxton. In his office, there is an intricate calendar that outlines the days of each billing cycle meter read, and within that cycle are the routes to run. Each year, the Meter Section will have around 1.7 million meter reads, with a 99.9% accuracy rate.

Each house Elliot drives by ticks down with a steady beep, beep, beep, and the little red dots disappear on the iPad until the neighborhood is cleared and he moves on to another subdivision. On this day, he has 5,636 residential addresses on his list.

Firsthand knowledge taught him that some new homes are not marked on the primary address list that guides his section, but they are registered as a meter to be read.

“I learned where these addresses were by doing it,” he said. “If you miss them, and then leave your area, you have to turn back around and go read them. That takes a lot of time if the section you are reading is all the way in Bethel or Ayden and you’re already back in Greenville.”

He said making sure the thousands of meters read can seem daunting, but after putting in time on the job, it is something that becomes second nature. “You just learn how to do it, you learn where to go, and how to make it efficient. Everybody will read differently with how it works for them,” he said.

Elliot rides these routes alone and he enjoys the flexibility in being able to get the job done in the way that works best for him.

Calvin Glover, Meter Field Technician III on the service side of the Meter Section, said being a lone worker offers Meter Techs the independence to make in-the-moment decisions. “I enjoy the autonomy of being a lone worker,” Calvin said. “It helps you gain confidence because of the opportunity to make your own decisions in the field.”

Having that autonomy is important when being faced with making immediate judgment calls, especially when the thousands of customers being served by GUC most often see these employees first, and situations have the potential to be a challenge. It takes patience, de-escalation skills, courage, and a certain amount of empathy to handle tough circumstances.

“You have to know how to talk with people. I’ve been here for a long time, and I’ve really learned how. Cut-off days aren’t so bad once you learn how to speak to customers and understand them. I approach this work in a humble and positive way,” Calvin said.

When he arrives at Wimbledon Drive for a customer requested disconnect, he hops out of his truck and approaches the meter he was tasked to disconnect.

“Hey, you’re not turning off lights, are you? Because I paid my bill,” said a woman who was getting out of her car. Calvin congenially smiled and said, “Oh no, ma’am, that’s not what we are doing today. You have a good morning.” She smiled, nodded, and waved back, and he got back into his truck and said, “See, you just have to know how to talk to people.”

Meter service technicians complete all service-related orders, including connections and disconnections. Allen Lyles, Meter Supervisor (Service), oversees this area of Meter and coordinates the 24/7 call rotation, making sure that all service-related orders are completed. Maintaining a continuous presence for reporting necessary repairs, starting, stopping, and disconnecting services is paramount in ensuring usage data and secure services.

The Foundation

The Meter Section is housed in the Electric Department but is unique in that it covers every service GUC has to offer. Meter Superintendent Jason Hardee oversees the four divisions within the Meter Section – Reading, Water/Gas Repair, Electric Repair, and Service.

With so many moving parts, Meter’s administrative arm plays a vital role. Autumn Pollard, Staff Support Specialist II, puts much of her focus on the details that run the day-to-day work of the crews in each section. From troubleshooting Cityworks to handling CCS and billing concerns, Autumn’s work centers on making sure Meter runs seamlessly, which is important considering how many GUC services hinge on this section’s competency and efficiency.

“There are regulations that govern Electric services, but there are also specific regulations that govern Water and Natural Gas services. I have to know all of them and stay up to date with regulatory changes,” Jason said.

Jason monitors industrial data seven days a week to ensure billing is correct and data collection is on point. The section’s attention to detail and consistent vigilance is a necessity for the success of GUC and economic development in the area. Accurate data and meter reads are a matter of millions of dollars saved or lost.

“We have to make sure everything is running properly to capture the right data,” Jason said. To collect this data appropriately, the equipment must be performing at optimal levels.

“We go beyond the standards,” said Supervisor Meter Repair (Gas and Water) Holden Rouse, who oversees the testing and repairs of more than 68,000 water and gas meters.

These employees can test and calibrate between 30-40 meters a day. When those meters in question don’t pass the calibration tests, a technician adjusts a set of three screws within. This recalibration process requires precise turns of each screw.

“A pro can do a recalibration on one try, it could be two to three times for a seasoned technician, but still sometimes it can take up to five tries to get it right. We always get it right before we send these back out,” Holden said as Meter Field Technician II Brandon Garris watched the meter calibrator click from yellow indicators to green indicators after he twisted a few screws.

The Gas and Water Meter Repair section will see between 1,500-2,000 meters a year that have reached the end of their 15-year or 30-year life cycle. Some will be calibrated, scraped, painted, and redistributed, while some will be put in a junk pile.

The small meters land in the repair shop. The industrial customers with water lines larger than two inches will have technicians go out on the site to test meter accuracy.

“We send a three-man crew to check those,” said Keith Nichols, Meter Technician III. “These are confined spaces and there are more things involved.”

When considering large-scale load management and industrial metering loads, it all begins with the information that Meter gathers on customer usage, customer-owned generators, and GUC-owned generators. “The more we shed, the less we pay in wholesale during peaks,” Jason said.

Electric Meter Repair Supervisor Brandon Smith said electric metering is complex, and for his part, he oversees the electric meter testing, installation, and repair of residential electric meters, but also higher amp load customers (industrial, commercial, and large residential users), solar customers, and solar farms that are operational in the area.

“We verify that all equipment is accurate and working properly for our Current Transformer (CT) customers,” said Blake Horton, Electric Meter Specialist, as he tests a newer commercial meter at Royal Farms off of Old Pactolus Highway and Greenville Boulevard.

“Repair and maintenance go hand-in-hand. Occasionally, we will find a problem while we are out doing routine testing. If it’s not accurate information, billing will not be right, and we don’t want that for us or the customer because these are high-usage facilities.”

For CT customers, specialists use a three-phase test that must read voltage as accurately as possible, while comparing the ratio from the service and the meter transformer side.

“We calibrate 400 to 600 per year, and we manage the change-out program for CT customers every four years,” Brandon said. Brandon also said that, right now, Technicians bring meters back to recalibrate them, but when Advanced Metering Infrastructure (AMI) comes in, that can be done in the field.

On the Horizon

The Meter Section is expected to see some big changes with the replacement of the current Advanced Meter Reading (AMR) technology with AMI.

AMI can change how reading, cutoff, stop, start, and repair services are done. For instance, if a customer is on the cutoff list, with AMI, a Meter Technician does not need to go out to the property and manually turn it off, it is done remotely. When that same customer pays the bill, instead of having a technician go back to turn it on, the system does it remotely, right away.

While this is a safer alternative for Meter Technicians, automated data collection from AMI can also offer more accurate electric peak data information and real-time water and gas usage data.

“When AMI comes into play, we will have more data coming in all the time. This will be good because we can be more proactive and won’t miss metering problems. Currently, we don’t have the ability to monitor or address meter problems in real time such as tampering and possible loose connections that cause heat damage. AMI will change how the Meter Section does everything,” said Jason.